Lean MANUFACTURING

In an effort to maintain our competitive edge in this industry, we have embraced Lean Manufacturing Concepts. This is a top level driven approach. For jobs matching our Cells or married processes, we offer significantly reduced cycle times and customer pleasing pricing. Continuous improvement has us constantly addressing our customer quality, price, and delivery expectations. We are integrated into our customer Kanban systems, and our partnering has matured us into a shared responsibility approach on delivery to a downstream customer’s needs.

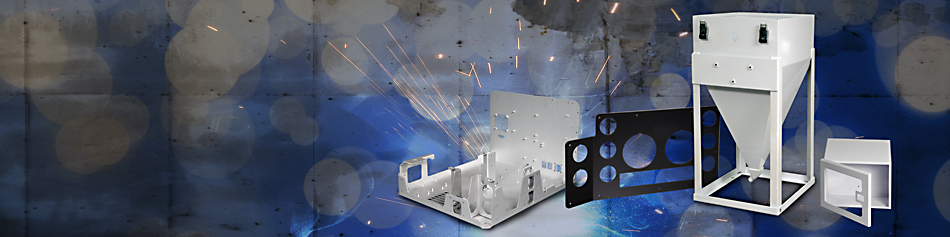

Assembly

For customers that require more than a basic Fabricating shop, we offer follow-up labor in: riveting, mechanical retaining or conventional electro-mechanical assembly. We can provide point-to-point wiring with crimped or soldered interconnection. To ensure the quality of our assembled products, we conduct Hi-pot testing, basic continuity checks, or we can physically run-in/burn-in the assembly.

J.P. Bell can also act as a shipping point for contract products. We can assemble, test and package products for delivery to your customers after assembly. This saves the non-value added costs of transportation, inventory and shipping to your site. Call J.P. Bell to explore the possibilties.

Welding

We are a full service welding facility providing MIG and TIG welding of stainless, CRS and aluminum. We also spot weld stainless and CRS.

Our welding department consist of:

• Lincoln pulsed MIG welding machines for close tolerance stainless and carbon steel applications with the added capability of using a Cobra push/pull gun for Aluminum. We can decorative weld down to 20 ga materials.

• Miller TIG welding machines

• A rotary table allows us to do smooth MIG welding when mating a round to a part requiring a full sealed weld

• #4 brush finish can be returned to a welded surface by using one of our two stroke sanders